-

Best Price

-

Good Quality

-

Alta pureza

-

Technically Supported

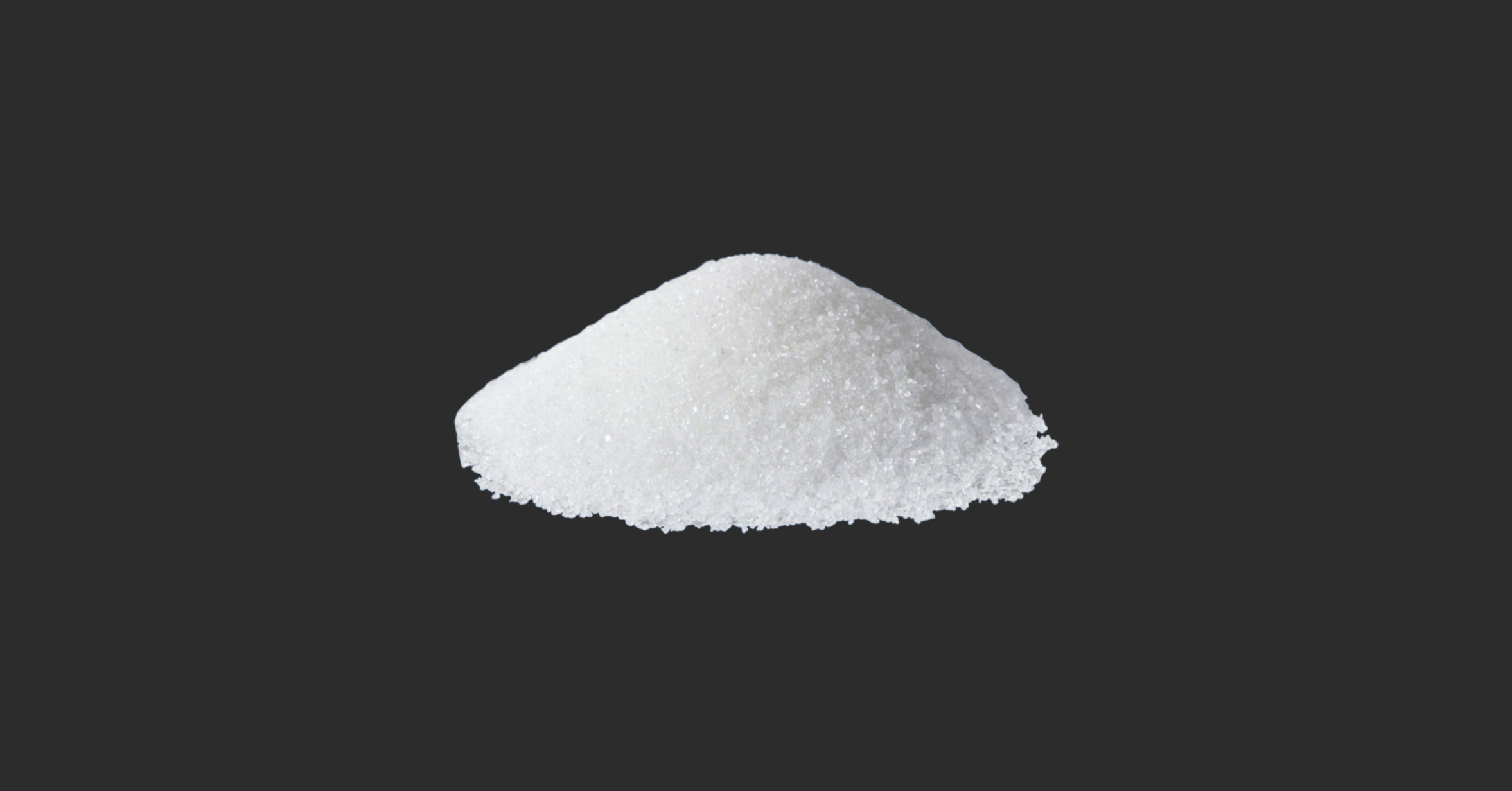

99.0% industrial-grade sodium nitrate powder is an important basic industrial raw material. With its outstanding oxidation performance and stable chemical properties, it plays a key role in many industrial fields such as glass manufacturing, metal processing, and chemical synthesis. The high-purity products we offer ensure batch consistency, providing reliable support for your production process and are the ideal choice for enhancing product quality and production efficiency.

The core value of industrial-grade sodium nitrate

Sodium nitrate (NaNO₃), as a multifunctional industrial compound, its value mainly lies in:

- Strong oxidizing property: It can effectively decompose and release oxygen in high-temperature environments, promoting combustion reactions and oxidation processes.

- High-Efficiency nitrogen source: It provides a stable source of nitrate nitrogen for chemical reactions and industrial production.

- Excellent solubility: The powder form ensures rapid dissolution and uniform mixing.

- Thermal stability: It maintains chemical stability in various industrial environments

Our core product advantages

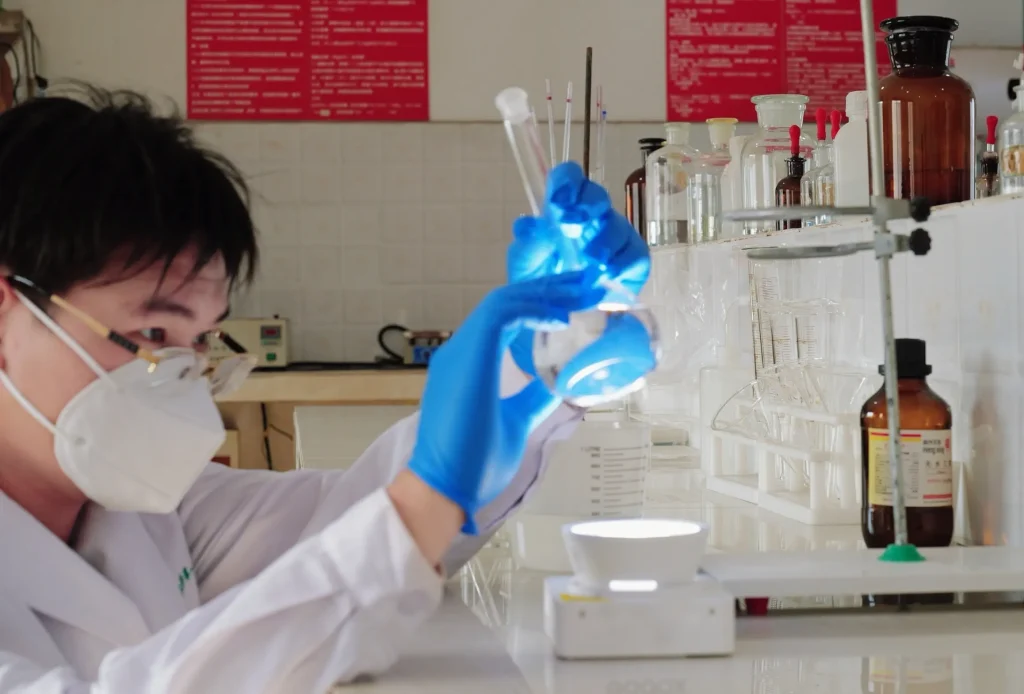

A strict quality control system

- Each batch of products undergoes strict laboratory testing to ensure a purity of over 99.0%.

- A complete quality traceability system is implemented to guarantee the traceability of product quality

Optimized particle size distribution

- The carefully controlled powder particle size ensures the best reaction efficiency and dissolution rate.

- The excellent fluidity facilitates automated feeding and precise metering

Reliable product consistency

- Advanced production techniques ensure a high degree of consistency in product quality across different batches.

- Professional warehouse management guarantees the stability of product performance

Technical parameters

| ltem | Standard Indicator(%) | Test Result (%) |

| Sodium Nitrate (NaNO 33), w/% ≥ | 98.0 | 99.0 |

| Sodium Nitrite (NaNO 22), w/%≤ | 0.10 | 0.02 |

| Moisture, w/%≤ | 2.0 | 1.4 |

| Chloride (as NaCl), w/%≤ | / | 0.78 |

| Sodium Carbonate (Na 22CO 33), w/%≤ | 0.10 | 0.05 |

| Water Insoluble Matter, w/%≤ | / | 0.02 |

| Iron (Fe), w/%≤ | 0.005 | 0.0006 |

Main application fields

Glass industry

- As an efficient clarifying agent, it effectively removes bubbles from glass melts.

- It serves as an oxidant to prevent glass discoloration and enhance the light transmittance of products.

- It is suitable for the production of float glass, vessel glass, and special glass

Metal processing industry

- An important component of heat treatment salt bath

- Key raw material for metal blackening treatment

- Auxiliary material for aluminum oxidation treatment and quenching process

Chemical synthesis

- Basic raw materials for manufacturing other nitrate products

- Dye intermediates and oxidants for explosive production

- raw materials for the preparation of chemical catalysts

Other industrial applications

- Oxidants and fluxes for the ceramic industry

- Oxidizing components for fireworks and firecrackers

- corrosion inhibitors for water treatment

Packaging, Storage and Safety Instructions

- Packaging: Inner packaging is polyethylene film bags, outer packaging is polypropylene woven bags, with a net weight of 25 kilograms /50 kilograms/1ton per bag, or customized according to customer requirements

- Storage conditions: Cool and dry place , warehouse temperature ≤30℃, relative humidity ≤80%.

- Transportation specifications: Hazard Code No. UN 1498, use sealed packaging, shipped separately.

FAQ

Q1: What are the main differences between sodium nitrate and sodium nitrite?

A: Although they are all sodium nitrates, sodium nitrate is a strong oxidant and is mainly used in industries such as glass and metal processing. Sodium nitrite has a certain reducing property and is mainly used in metal heat treatment and food processing (with limited use). There are significant differences between the two in terms of chemical properties and application fields.

Q2: How can we ensure that the product does not clump during storage?

A: We ensure that the product maintains good fluidity through strict humidity control, optimized particle size distribution and appropriate packaging materials. It is recommended that customers keep the storage environment dry and avoid damage to the packaging.

Q3: Can customized product specifications be provided?

A: We can provide customized services in terms of purity, particle size, packaging, etc. based on the special requirements of customers to ensure that the product is most suitable for your production process.

Consult now to get an exclusive quote!

Welcome to contact us for the latest product information and detailed technical parameters. Our professional team will provide you with the highest quality product services and professional technical support. We look forward to establishing a long-term cooperative relationship with you.

Categoria de produto

-

Deixe um recado!

Deixe um recado!

-powder-2.webp)

-powder.webp)