-

Best Price

-

Good Quality

-

نقاء عالي

-

Technically Supported

High-purity photoelectric grade sodium nitrate is an ultra-high-purity electronic chemical specially designed for high-end photoelectric glass such as mobile phone screens and flat panel displays. This product is a colorless and transparent crystal or a solution of a specific concentration, prepared through precise processes such as ion exchange and double decomposition. It strictly controls the content of metal impurities (such as Fe≤3.0mg/L), the number of particulate matter, and the residual nitrite (NaNO₂ < 0.018%). Ensure that in the precise etching of liquid crystal panels (LCD/OLED) and touch screen cover glass, clarification of glass substrates, and surface treatment, display defects, color spots, and reduced light transmittance caused by impurities are eliminated, meeting the G4 grade or above wet electronic chemical standards.

Key product features and indicators

| Test Item | Standard Requirement | Test Result |

| Sodium Nitrate (NaNO₃) (dry basis) | ≥99.9 | 99.92 |

| pH Value | 5.5—7.5 | 6.12 |

| Clarity Test | ≤3 | 3 |

| Water Insoluble Matter, % | ≤0.005 | 0.0019 |

| Total Chloride (as Cl), % | ≤0.005 | <0.005 |

| Iodate (as IO₃), % | ≤0.002 | <0.002 |

| Sulfate (as SO₄), % | ≤0.01 | <0.01 |

| Nitrite (as NaNO₂), % | ≤0.001 | <0.001 |

| Ammonium (as NH₄), % | ≤0.005 | <0.005 |

| Phosphate (as PO₄), % | ≤0.001 | <0.001 |

| Potassium (K), % | ≤0.01 | 0.0024 |

| Calcium (Ca), % | ≤0.001 | 0.00014 |

| Iron (Fe), % | ≤0.0005 | <0.0005 |

| Magnesium (Mg), % | ≤0.001 | 0.000018 |

| Na₂CO₃, % | ≤0.01 | 0.0013 |

| Borate, % | ≤0.0005 | <0.0005 |

| Heavy Metals (as Pb), % | ≤0.001 | <0.001 |

Customized service: We support customization for solutions of different concentrations, crystal particle sizes, and ultra-low specific metal ions (such as Cu≤0.03ppb) to meet your requirements for automated production lines.

Core functions and application fields

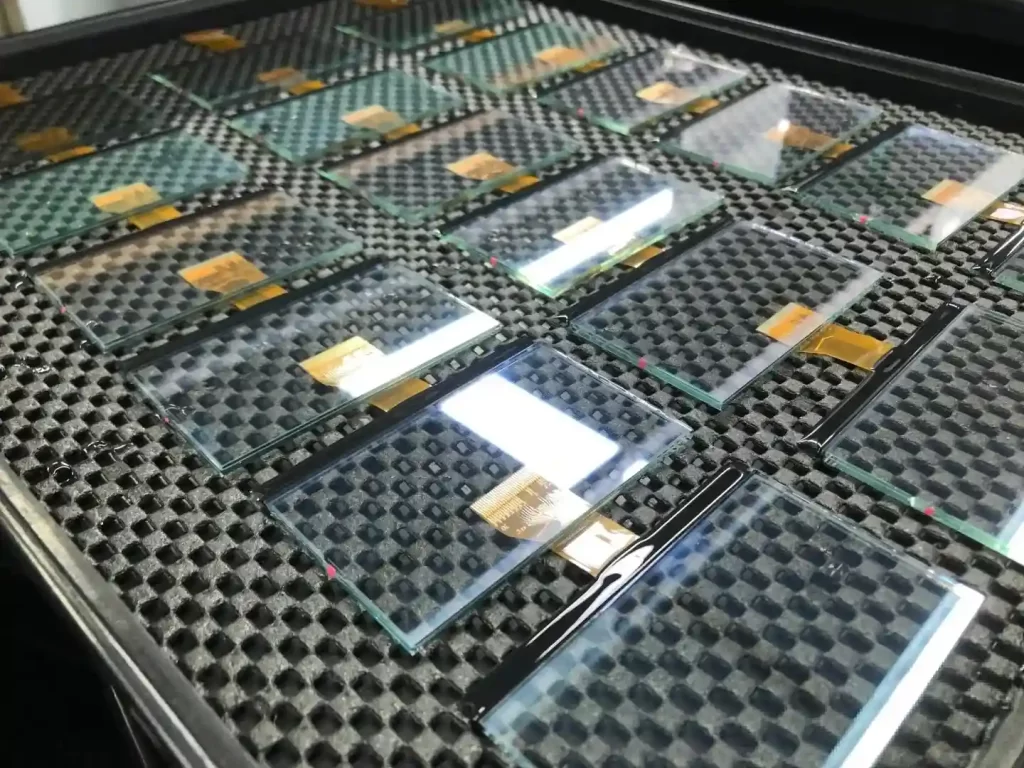

Manufacturing of mobile phone screen glass

- Glass substrate clarification and decolorization: In high-temperature melting, sodium nitrate, as an oxidizing flux, can effectively promote the discharge of bubbles, significantly enhance the light transmittance and uniformity of the glass, and prevent dark spots or uneven brightness on the screen.

- Surface etching and polishing: It is used to prepare precision etching solutions, perform micron-level processing on the glass surface, ensure the flatness and ultra-thin tolerance of the screen, and lay the foundation for subsequent coating processes.

- Ion enhancement: In a chemically strengthened salt bath, high-purity sodium nitrate can assist in achieving sodium-potassium ion exchange, thereby enhancing the impact resistance and scratch resistance of the screen glass.

Other photoelectric display applications

- Liquid crystal panel (LCD) : Used in the cleaning and etching processes of TFT arrays to remove fine impurities and ensure circuit accuracy.

- OLED display: In the treatment of flexible substrates, the stability of high-purity sodium nitrate helps maintain the structural integrity of organic light-emitting materials.

- Photovoltaic glass and electronic ceramics: As functional additives, it is used for ultra-white photovoltaic glass cover plates and ceramic substrates of electronic components.

High-end special glass

In fields such as optical glass, instrument covers, and protective Windows, high-purity sodium nitrate, as a clarifying and decolorizing agent, can effectively remove bubbles and colored impurities in the glass melt, ensuring the high transmittance and optical performance of the products.

Packaging and storage and transportation

- Packaging specifications:Crystals: 25kg per bag (coated woven bag, lined with polyethylene bag).

- Storage conditions: Store in a cool, dry, well-ventilated warehouse, away from heat sources and fire, and avoid co-storage with reducing agents, flammable materials, and strong acids.

- Transportation requirements: Transport as general chemicals. Handle with care during loading and unloading to prevent damage and moisture.

Our advantages

- Purity limit guarantee: The main content of the product is ≥99.9%, and key metal impurities are controlled at the mg/L to ppb level, ensuring your screen yield rate from the source.

- Technical adaptability: Relying on a professional R&D team, we can provide technical support such as formula optimization and targeted impurity control to solve your specific problems in the manufacturing of new screen glass.

- Stable supply system: Strict raw material control and automated production lines ensure highly consistent product batches, meeting the demands of continuous large-scale production.

- Quick Response Service: We offer free samples and detailed technical data (COA, MSDS), and our professional team will respond to inquiries within 24 hours.

FAQ

How can we ensure that the purity of the product is not affected during transportation and storage?

We use multi-layer sealed waterproof packaging (with food-grade polyethylene inner bags) and provide constant temperature and humidity warehouses. It is recommended that you store the goods in a clean and dry environment after arrival. IBC barrel solution should be given priority to reduce the risk of contamination when opening the lid.

Q3: Can you provide ultra-low copper ion (Cu²⁺) products required for the new generation of OLED screens?

Sure. We have developed a specially made grade sodium nitrate with Cu²⁺ ≤ 0.03ppb, specifically designed for OLED and Micro-LED screens that are extremely sensitive to heavy metals. We welcome you to request a special test report.

Contact us immediately to obtain your exclusive high-purity solution and samples!

If you are looking for a reliable high-purity sodium nitrate partner to improve the yield rate of screens and overcome material bottlenecks, please contact us immediately. Click on “Online Consultation” or send an email to get a free sample application channel and professional technical solutions.

فئة المنتج

- واتساب

-

ترك رسالة!

ترك رسالة!