-

Best Price

-

Good Quality

-

High Purity

-

Technically Supported

99.9% high-purity potassium nitrate powder is a high-quality raw material specially used for chemical strengthening of mobile phone glass

Our 99.9% high-purity potassium nitrate powder is a core raw material specially developed for the chemical strengthening of high-end window touch protection glass panels in mobile phones, digital products, automotive touch control, smart wearables and smart home devices. This product has obtained EU REACH certification and complies with the world’s most stringent environmental protection and safety regulations.The main content is ≥99.9%. It features ultra-high purity, low impurities, and excellent chemical activity, which significantly improves the stress value, surface flatness, appearance yield, and tempering life of glass covers. The product quality has consistently maintained a leading level in China.

Core advantages of the product

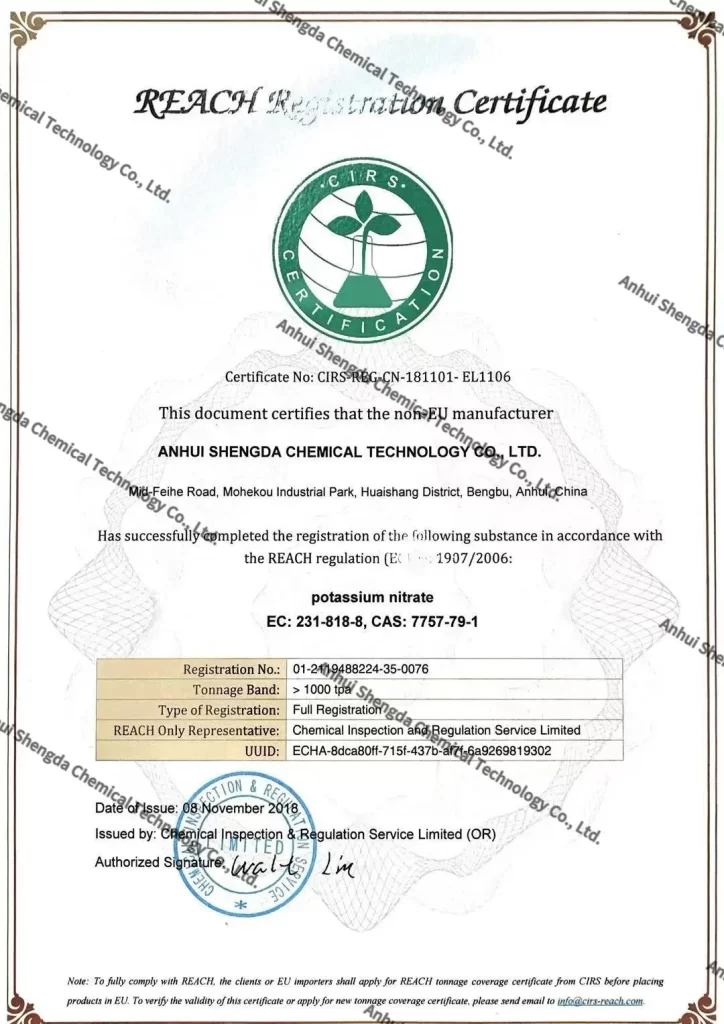

The only EU REACH certification in China

The EU REACH certification is regarded as one of the strictest and most complex chemical management systems in the world. Obtaining this certification means:

- Compliance and safety: The ingredients of our products have undergone comprehensive assessment and registration, fully meeting the high standards of the European Union for human health and environmental safety.

- Unobstructed market access: Glass products made from our raw materials have a greater advantage in terms of chemical compliance when exported to the EU and many other international markets that recognize this standard, thus clearing significant trade barriers.

- The ultimate endorsement of quality,Choosing us means that the starting point of your supply chain is equipped with international-level quality and safety genes.

Ultra-high purity and outstanding performance

- Purity ≥99.9% : Far exceeding industry standards, ensuring more thorough and stable reactions during chemical intensification.

- Excellent tempering effect: The glass strengthened with this product outperforms the industry standard in key indicators such as stress value, impact resistance, wear resistance and concave-convex control.

- Low heavy metals and chloride ions: The extremely low impurity content prevents contamination or corrosion of the glass surface during the tempering process, making it particularly suitable for optical glass with extremely high cleanliness requirements.

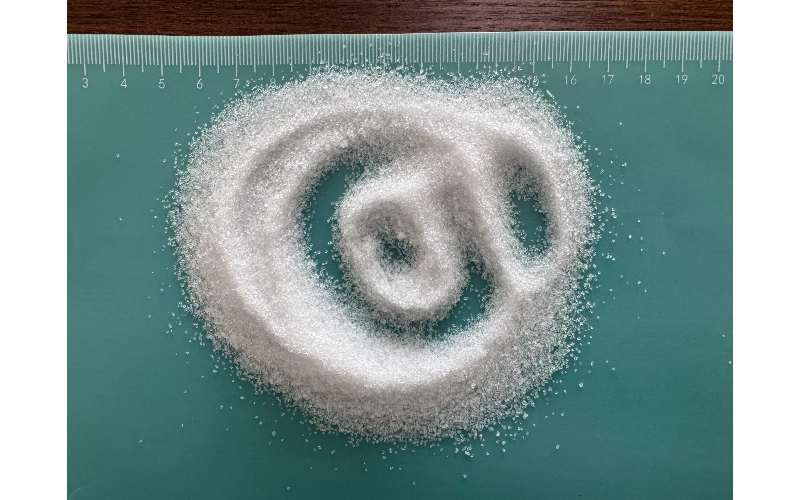

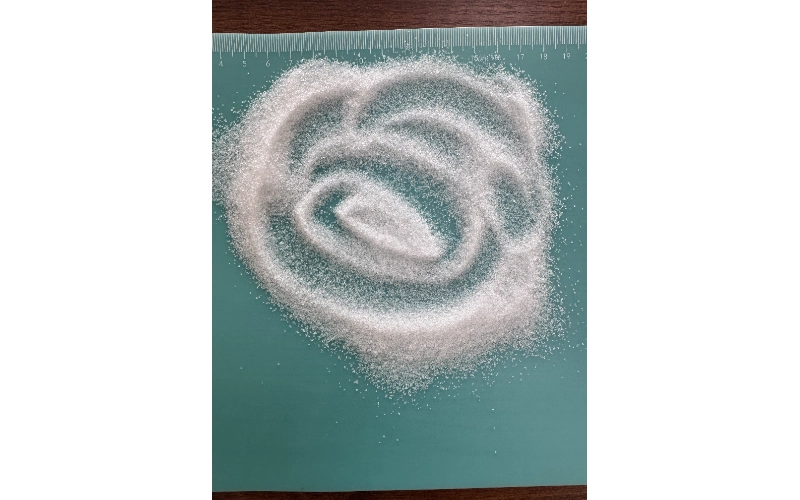

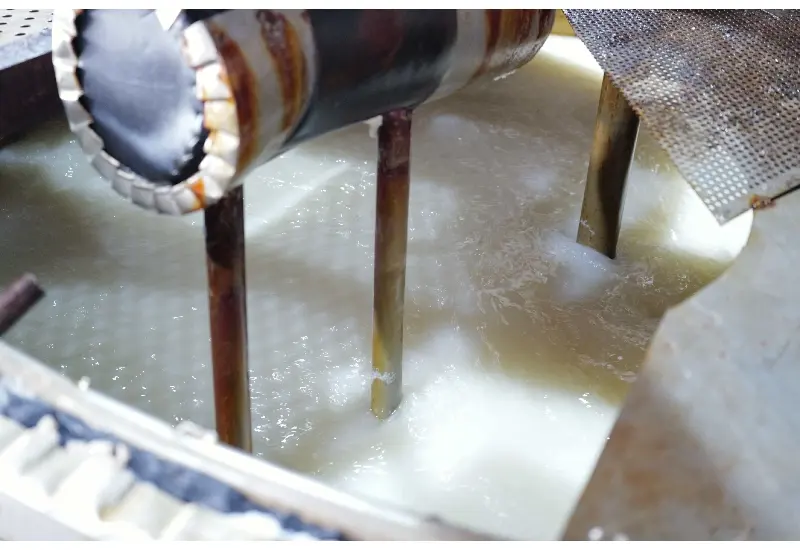

Advanced vacuum crystallization production technology

We produce using our independently developed vacuum crystallization process. This process can precisely control crystal growth. The resulting potassium nitrate particles have high uniformity, good fluidity and are not prone to caking, thus ensuring that they can maintain stable chemical activity and a longer service life even after long-term use in the glass tempering tank.

Improve efficiency and yield

High-purity raw materials mean less impurity interference, which can effectively reduce the defect rate during the glass strengthening process and bring higher output efficiency and economic benefits to your production line.

Parameter (Molten salt grade)

| Test Item | Technical Indicator | Test Result |

| Potassium nitrate (KNO₃) | ≥ 99.9% | 99.91 |

| PH Value | 5.0-8.0 | 5.80 |

| Water Insolubles | ≤ 0.05% | 0.0016 |

| Chloride ion (Cl⁻) | ≤ 0.005% | <0.0025 |

| Iodate (IO₃) | ≤ 0.002 | <0.002 |

| Sulfate (SO₄) | ≤ 0.01 | <0.003 |

| Nitrite (NO₂⁻) | ≤ 0.001% | <0.001 |

| Ammonium (NH₄) | ≤ 0.005 | <0.005 |

| Phosphate (PO₄) | ≤ 0.001 | <0.001 |

| Sodium(Na) | ≤ 0.02 | 0.00059 |

| Calcium (Ca) | ≤0.001% | 0.00015 |

| Magnesium (Mg) | ≤0.001 | 0.000048 |

| Iron (Fe) | ≤0.0005 | <0.0004 |

| Heavy Metals (as Pb) | ≤ 0.001 | <0.001 |

Application field

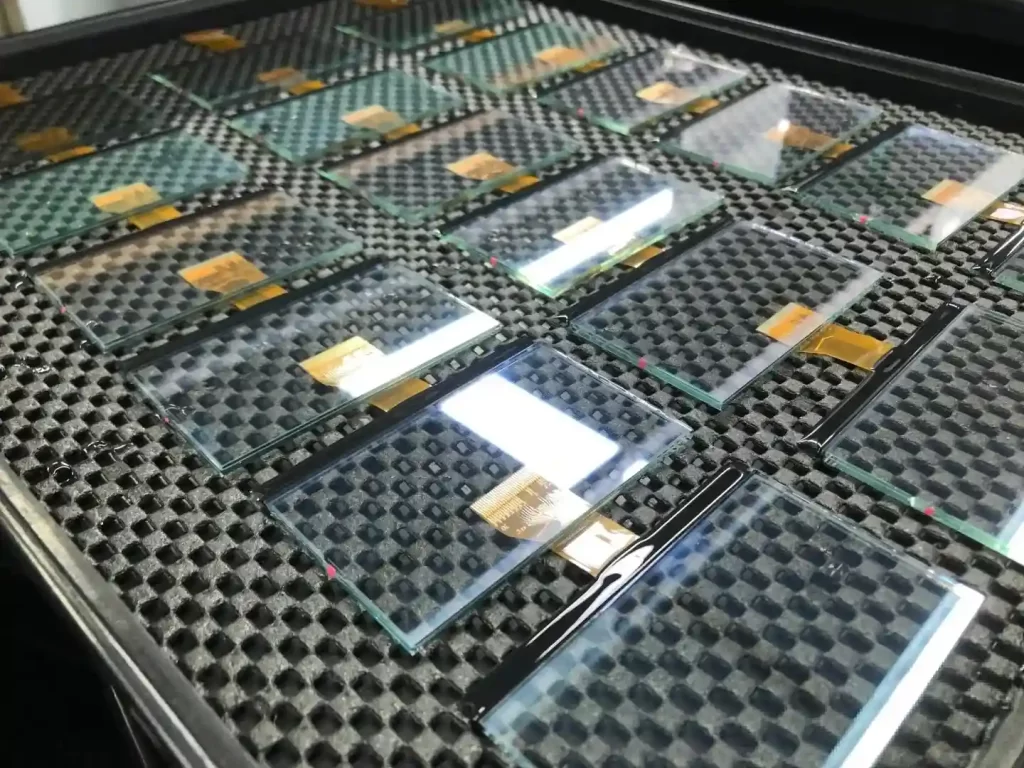

- Main applications: Chemical strengthening of glass covers for mobile phone touch screens.

- Other applications: Widely used as a chemical strengthening agent for optical glass in computer tablet displays, automotive central control touch screens, and various industrial instrument touch screens.

High-end industrial manufacturing

- As a glass clarifying agent, it is used in the production of high-end glass products such as automotive lamp glass, optical glass and picture tube glass shells

- It is used in the metal heat treatment industry as a component of quenching salt baths

Packaging, Storage and Safety Instructions

- Packaging: 25/50 kilograms or 1ton per bag

- Storage: Keep in a cool, dry and well-ventilated warehouse. Keep away from fire sources, heat sources and reducing substances.

- Safe Operation: During the operation of the molten salt system, the medium must be kept clean. It is strictly forbidden to come into contact with water, organic matter and reducing substances to avoid triggering violent chemical reactions.

- Strictly control the heating rate to avoid sudden cooling and heating of the system.

Why choose us?

- Professional and reliable suppliers: We have stable cooperation with well-known domestic glass cover plate enterprises such as Lens Technology, Bern Optics, and BOE. Our products are supplied in large quantities to the supply chain systems of domestic and foreign brand mobile phones such as Apple, Samsung, and Huawei.

- Technology and Quality Benchmarks: As one of the drafters of national standards, we continuously invest in technological research and development to ensure the leading and stable quality of our products.

- Comprehensive quality assurance: The product has passed the HF and RoHS certifications of the authoritative third-party SGS company , meeting strict international environmental protection and safety standards.

FAQ

Q1: Why is 99.9% purity critical for potassium nitrate used in mobile phone screens?

A: Our 99.9% ultra-high purity is fundamental because even trace impurities can cause surface corrosion, stress marks, or “hazing” on the glass during the chemical strengthening process. This directly translates to higher production yields and superior final product quality, ensuring the flawless clarity and strength demanded by premium mobile devices.

Q2: How does your product’s low chloride and sulfate content benefit the manufacturing process?

A: We maintain exceptionally low levels of chlorides and sulfates. These aggressive impurities are known to corrode the molten salt bath and the sensitive glass surface. By minimizing them, our product significantly extends bath life, reduces maintenance costs, and, most importantly, prevents surface defects that would otherwise compromise screen integrity and optical perfection.

Q3: Is your product compliant with industry standards for chemical strengthening?

A: Absolutely. Our potassium nitrate is formulated to meet and exceed stringent industry standards like HG/T 6241-2023, which is specifically designed for chemical strengthening applications. This guarantees consistent performance and reliability for high-end manufacturing.

Q4: What are the advantages of your powder’s specific physical properties?

A: Our powder is engineered for optimal flowability and rapid dissolution. This ensures a uniform and stable molten salt bath, which is crucial for achieving a consistent depth of the compressive stress layer (DOL) across every batch of glass. This uniformity is key to predictable and superior mechanical performance in every screen.

Q5: Can you ensure a stable and qualified supply for large-scale production?

A: Yes. We operate a robust supply chain with stringent quality control from raw materials to finished product. This allows us to provide a consistent, high-volume supply that meets the rigorous demands and tight production schedules of major mobile device supply chains, giving you complete confidence in your sourcing.

Consult now to get exclusive samples and solutions

If you are looking for high-performance and highly stable potassium nitrate raw materials for your mobile phone glass production line, our 99.9% high-purity potassium nitrate powder will be your ideal choice. Welcome to contact us for free samples and detailed technical data. Our expert team will provide you with professional technical support.

Product Category

-

Leave a message!

Leave a message!